- Ignition Casino Wire Transfer Withdrawal

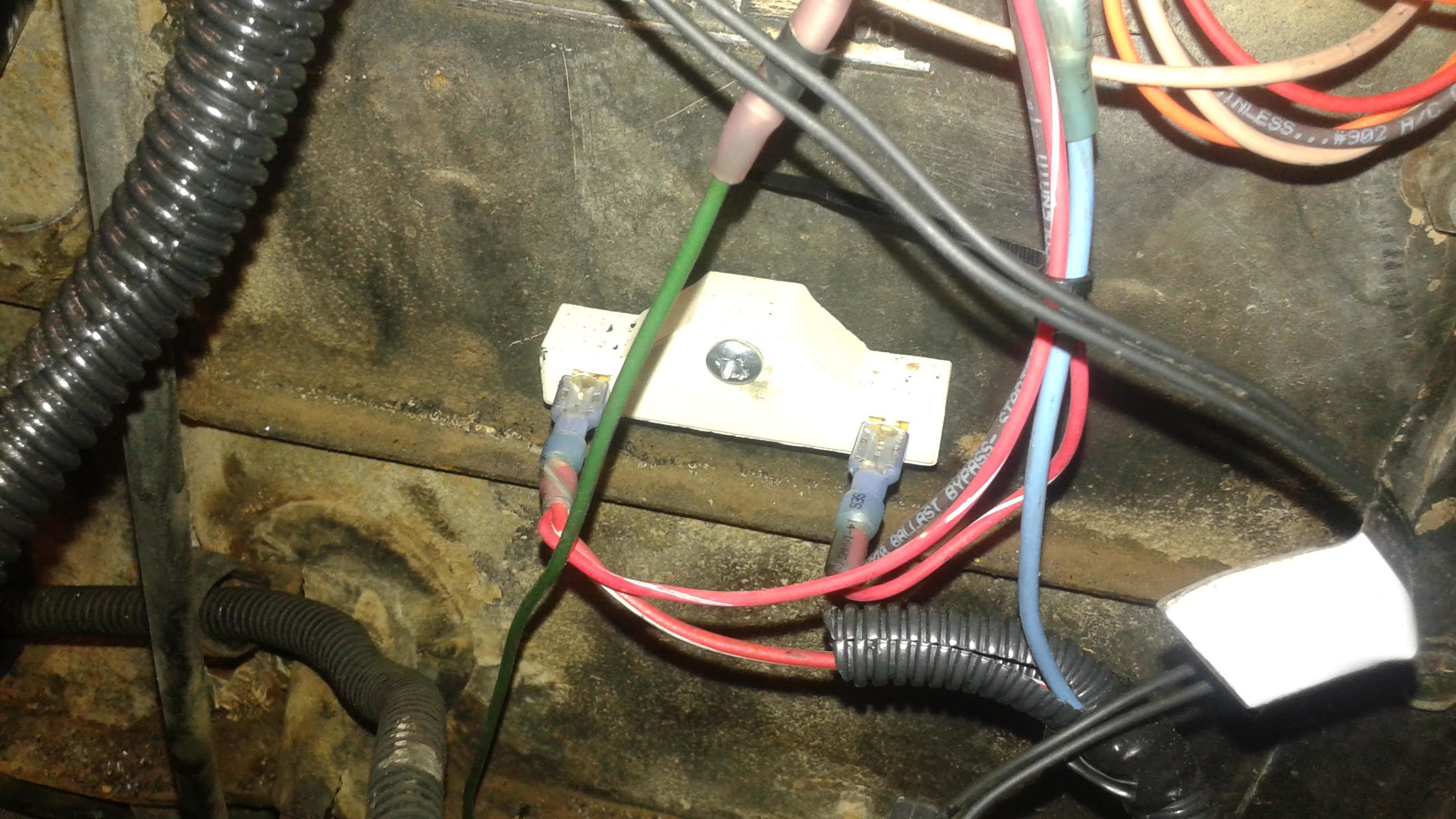

- 6 Wire Ignition Switch Diagram

- Ignition Coil Wire Resistance Chart

From there, a wire takes this current over to the distributor and is connected to a special on/off switch, called the points. When the points are closed, this current goes directly to ground. When current flows from the ignition switch, through the windings in the coil, then to ground, it builds a strong magnetic field inside the coil. The Basic Wiring Configuration for a Typical Generator Transfer Switch: LINE (top) – The power from the Electric Utility Company – Normal Power. LOAD (center) – The Connection to the Home Electrical. The coil is a simple device - essentially a high-voltage transformer made up of two coils of wire. One coil of wire is called the primary coil. Wrapped around it is the secondary coil. The secondary coil normally has hundreds of times more turns of wire than the primary coil. Current flows from the battery through the primary winding of the coil. Associate all ignition wire conductors with original equipment and replacement ignition wire carbon conductors (which progressively fail as a result of microscopic carbon granules burning away and thus reducing the spark energy to the spark plugs) and with solid wire zero-resistance conductors. TPC Wire & Cable Corp. Offers two Thermo-Trex ® igniter wires that are both RoHS Compliant and feature nickel-plated copper conductors. Both have high UL ratings with one offering a mica tape-wrap insulation system and the other a fluoropolymer jacket. Applications for our igniter.

An ignition magneto, or high tension magneto, is a magneto that provides current for the ignition system of a spark-ignition engine, such as a petrol engine. It produces pulses of high voltage for the spark plugs. The older term tension means voltage.[1]

The use of ignition magnetos is now confined mainly to engines where there is no other available electrical supply, for example in lawnmowers and chainsaws. It is also widely used in aviation piston engines even though an electrical supply is usually available. In this case, the magneto's self-powered operation is considered to offer increased reliability; in theory, the magneto should continue operation as long as the engine is turning.

History[edit]

Firing the gap of a spark plug, particularly in the combustion chamber of a high-compression engine, requires a greater voltage (or higher tension) than can be achieved by a simple magneto.[2] The high-tension magneto combines an alternating current magneto generator and a transformer.[2] A high current at low voltage is generated by the magneto, then transformed to a high voltage (even though this is now a far smaller current) by the transformer.[2]

The first person to develop the idea of a high-tension magneto was Andre Boudeville, but his design omitted a condenser (capacitor); Frederick Richard Simms in partnership with Robert Bosch were the first to develop a practical high-tension magneto.[3]

Magneto ignition was introduced on the 1899 DaimlerPhönix. This was followed by Benz, Mors, Turcat-Mery, and Nesseldorf,[4] and soon was used on most cars up until about 1918 in both low voltage (voltage for secondary coils to fire the spark plugs) and high voltage magnetos (to fire the spark plug directly, similar to coil ignitions, introduced by Bosch in 1903).[4]

Operation[edit]

In the type known as a shuttle magneto, the engine rotates a coil of wire between the poles of a magnet. In the inductor magneto, the magnet is rotated and the coil remains stationary.

As the magnet moves with respect to the coil, the magnetic flux linkage of the coil changes. This induces an EMF in the coil, which in turn causes a current to flow. One or more times per revolution, just as the magnet pole moves away from the coil and the magnetic flux begins to decrease, a cam opens the contact breaker (called 'the points' in reference to the two points of a circuit breaker) and interrupts the current. This causes the electromagnetic field in the primary coil to collapse rapidly. As the field collapses rapidly there is a large voltage induced (as described by Faraday's Law) across the primary coil.

As the points begin to open, point spacing is initially such that the voltage across the primary coil would arc across the points. A capacitor is placed across the points which absorbs the energy stored in the leakage inductance of the primary coil, and slows the rise time of the primary winding voltage to allow the points to open fully.[5] The capacitor's function is similar to that of a snubber as found in a flyback converter.

A second coil, with many more turns than the primary, is wound on the same iron core to form an electrical transformer. The ratio of turns in the secondary winding to the number of turns in the primary winding, is called the turns ratio. Voltage across the primary coil results in a proportional voltage being induced across the secondary winding of the coil. The turns ratio between the primary and secondary coil is selected so that the voltage across the secondary reaches a very high value, enough to arc across the gap of the spark plug. As the voltage of the primary winding rises to several hundred volts,[5][6] the voltage on the secondary winding rises to several tens of thousands of volts, since the secondary winding typically has 100 times as many turns as the primary winding.[5]

The capacitor and the coil together form a resonant circuit which allows the energy to oscillate from the capacitor to the coil and back again. Due to the inevitable losses in the system, this oscillation decays fairly rapidly. This dissipates the energy that was stored in the condenser in time for the next closure of the points, leaving the condenser discharged and ready to repeat the cycle.

On more advanced magnetos the cam ring can be rotated by an external linkage to alter the ignition timing.

Ignition Casino Wire Transfer Withdrawal

In a modern installation, the magneto only has a single low tension winding which is connected to an external ignition coil which not only has a low tension winding, but also a secondary winding of many thousands of turns to deliver the high voltage required for the spark plug(s). Such a system is known as an 'energy transfer' ignition system. Initially this was done because it was easier to provide good insulation for the secondary winding of an external coil than it was in a coil buried in the construction of the magneto (early magnetos had the coil assembly externally to the rotating parts to make them easier to insulate—at the expense of efficiency). In more modern times, insulation materials have improved to the point where constructing self-contained magnetos is relatively easy, but energy transfer systems are still used where the ultimate in reliability is required such as in aviation engines.

Aviation[edit]

Because it requires no battery or other source of electrical energy, the magneto is a compact and reliable self-contained ignition system, which is why it remains in use in many general aviation applications.

Since the beginning of World War I in 1914, magneto-equipped aircraft engines have typically been dual-plugged, whereby each cylinder has two spark plugs, with each plug having a separate magneto system. Dual plugs provide both redundancy should a magneto fail, and better engine performance (through enhanced combustion). Twin sparks provide two flame fronts within the cylinder, these two flame fronts decreasing the time needed for the fuel charge to burn. As the size of the combustion chamber determines the time to burn the fuel charge, dual ignition was especially important for the large-boreaircraft engines around World War II where it was necessary to combust the entire fuel mixture in a shorter time than a single plug could provide, in order to build peak cylinder pressure at the rpm desired.

Impulse coupling[edit]

Because the magneto has low voltage output at low speed, starting an engine is more difficult.[7] Therefore, some magnetos have an impulse coupling, a springlike mechanical linkage between the engine and magneto drive shaft which 'winds up' and 'lets go' at the proper moment for spinning the magneto shaft. The impulse coupling uses a spring, a hub cam with flyweights, and a shell.[7] The hub of the magneto rotates while the drive shaft is held stationary, and the spring tension builds up. When the magneto is supposed to fire, the flyweights are released by the action of the body contacting the trigger ramp. This allows the spring to unwind giving the rotating magnet a rapid rotation and letting the magneto spin at such a speed to produce a spark.[7]

Automobile[edit]

Some aviation engines as well as some early luxury cars have had dual-plugged systems with one set of plugs fired by a magneto, and the other set wired to a coil, dynamo, and battery circuit. This was often done to ease engine starting, as larger engines may be too difficult to crank at sufficient speed to operate a magneto, even with an impulse coupling. As the reliability of battery ignition systems improved, the magneto fell out of favour for general automotive use, but may still be found in sport or racing engines.[8][9]

See also[edit]

Firing the gap of a spark plug, particularly in the combustion chamber of a high-compression engine, requires a greater voltage (or higher tension) than can be achieved by a simple magneto.[2] The high-tension magneto combines an alternating current magneto generator and a transformer.[2] A high current at low voltage is generated by the magneto, then transformed to a high voltage (even though this is now a far smaller current) by the transformer.[2]

The first person to develop the idea of a high-tension magneto was Andre Boudeville, but his design omitted a condenser (capacitor); Frederick Richard Simms in partnership with Robert Bosch were the first to develop a practical high-tension magneto.[3]

Magneto ignition was introduced on the 1899 DaimlerPhönix. This was followed by Benz, Mors, Turcat-Mery, and Nesseldorf,[4] and soon was used on most cars up until about 1918 in both low voltage (voltage for secondary coils to fire the spark plugs) and high voltage magnetos (to fire the spark plug directly, similar to coil ignitions, introduced by Bosch in 1903).[4]

Operation[edit]

In the type known as a shuttle magneto, the engine rotates a coil of wire between the poles of a magnet. In the inductor magneto, the magnet is rotated and the coil remains stationary.

As the magnet moves with respect to the coil, the magnetic flux linkage of the coil changes. This induces an EMF in the coil, which in turn causes a current to flow. One or more times per revolution, just as the magnet pole moves away from the coil and the magnetic flux begins to decrease, a cam opens the contact breaker (called 'the points' in reference to the two points of a circuit breaker) and interrupts the current. This causes the electromagnetic field in the primary coil to collapse rapidly. As the field collapses rapidly there is a large voltage induced (as described by Faraday's Law) across the primary coil.

As the points begin to open, point spacing is initially such that the voltage across the primary coil would arc across the points. A capacitor is placed across the points which absorbs the energy stored in the leakage inductance of the primary coil, and slows the rise time of the primary winding voltage to allow the points to open fully.[5] The capacitor's function is similar to that of a snubber as found in a flyback converter.

A second coil, with many more turns than the primary, is wound on the same iron core to form an electrical transformer. The ratio of turns in the secondary winding to the number of turns in the primary winding, is called the turns ratio. Voltage across the primary coil results in a proportional voltage being induced across the secondary winding of the coil. The turns ratio between the primary and secondary coil is selected so that the voltage across the secondary reaches a very high value, enough to arc across the gap of the spark plug. As the voltage of the primary winding rises to several hundred volts,[5][6] the voltage on the secondary winding rises to several tens of thousands of volts, since the secondary winding typically has 100 times as many turns as the primary winding.[5]

The capacitor and the coil together form a resonant circuit which allows the energy to oscillate from the capacitor to the coil and back again. Due to the inevitable losses in the system, this oscillation decays fairly rapidly. This dissipates the energy that was stored in the condenser in time for the next closure of the points, leaving the condenser discharged and ready to repeat the cycle.

On more advanced magnetos the cam ring can be rotated by an external linkage to alter the ignition timing.

Ignition Casino Wire Transfer Withdrawal

In a modern installation, the magneto only has a single low tension winding which is connected to an external ignition coil which not only has a low tension winding, but also a secondary winding of many thousands of turns to deliver the high voltage required for the spark plug(s). Such a system is known as an 'energy transfer' ignition system. Initially this was done because it was easier to provide good insulation for the secondary winding of an external coil than it was in a coil buried in the construction of the magneto (early magnetos had the coil assembly externally to the rotating parts to make them easier to insulate—at the expense of efficiency). In more modern times, insulation materials have improved to the point where constructing self-contained magnetos is relatively easy, but energy transfer systems are still used where the ultimate in reliability is required such as in aviation engines.

Aviation[edit]

Because it requires no battery or other source of electrical energy, the magneto is a compact and reliable self-contained ignition system, which is why it remains in use in many general aviation applications.

Since the beginning of World War I in 1914, magneto-equipped aircraft engines have typically been dual-plugged, whereby each cylinder has two spark plugs, with each plug having a separate magneto system. Dual plugs provide both redundancy should a magneto fail, and better engine performance (through enhanced combustion). Twin sparks provide two flame fronts within the cylinder, these two flame fronts decreasing the time needed for the fuel charge to burn. As the size of the combustion chamber determines the time to burn the fuel charge, dual ignition was especially important for the large-boreaircraft engines around World War II where it was necessary to combust the entire fuel mixture in a shorter time than a single plug could provide, in order to build peak cylinder pressure at the rpm desired.

Impulse coupling[edit]

Because the magneto has low voltage output at low speed, starting an engine is more difficult.[7] Therefore, some magnetos have an impulse coupling, a springlike mechanical linkage between the engine and magneto drive shaft which 'winds up' and 'lets go' at the proper moment for spinning the magneto shaft. The impulse coupling uses a spring, a hub cam with flyweights, and a shell.[7] The hub of the magneto rotates while the drive shaft is held stationary, and the spring tension builds up. When the magneto is supposed to fire, the flyweights are released by the action of the body contacting the trigger ramp. This allows the spring to unwind giving the rotating magnet a rapid rotation and letting the magneto spin at such a speed to produce a spark.[7]

Automobile[edit]

Some aviation engines as well as some early luxury cars have had dual-plugged systems with one set of plugs fired by a magneto, and the other set wired to a coil, dynamo, and battery circuit. This was often done to ease engine starting, as larger engines may be too difficult to crank at sufficient speed to operate a magneto, even with an impulse coupling. As the reliability of battery ignition systems improved, the magneto fell out of favour for general automotive use, but may still be found in sport or racing engines.[8][9]

See also[edit]

References[edit]

| Wikimedia Commons has media related to Magnetos (ignition). |

- ^Selimo Romeo Bottone (1907). Magnetos for Automobilists, how Made and how Used: A Handbook of Practical Instruction in the Manufacture and Adaptation of the Magneto to the Needs of the Motorist. C. Lockwood and son.

- ^ abcCauldwell, O. (1941). Aero Engines: for Pilots and Ground Engineers. Pitman. p. 88.

- ^Kohli, P.L. (1993). Automotive Electrical Equipment. Tata McGraw-Hill. ISBN0-07-460216-0.

- ^ abG.N. Georgano, G.N. (1985). Cars: Early and Vintage, 1886-1930. London: Grange-Universal.

- ^ abc'Archived copy'. Archived from the original on 2015-09-18. Retrieved 2016-06-21.CS1 maint: archived copy as title (link)

- ^'Capacitors in Ignition Systems'. www.smokstak.com. Archived from the original on 9 July 2017. Retrieved 6 May 2018.

- ^ abcKroes, Michael (1995). Aircraft Powerplants. New York: Glencoe. p. 180.

- ^Munday, Frank (2006). Custom Auto Electrickery: How to Work with and Understand Auto Electrical Systems. MBI Publishing Company. p. 59. ISBN0-949398-35-7.

- ^Emanuel, Dave (1996). Small-block Chevy performance: modifications and dyno-tested combinations for high performance street and racing use. Penguin. p. 122. ISBN1-55788-253-3.

Since 1976, Magnecor has been the leading manufacturer of ignition wires used for competition, street, industrial, aerospace, and military applications. Magnecor uses a combination of proprietary core and wire combinations, creating wires that offer the best noise suppression and longest durability in the marketplace. Magnecor provides spark plug wires and individual wires for almost every engine ever made. Simply put, Magnecor makes the most technically advanced ignition cables.

PERFORMANCE

Performance applications demand ignition cables that transfer high energy from the coil to plug, ensuring the most optimal ignition event for creating the most powerful combustion event. Magnecor's combination of a proprietary core and engineered windings, ensure that our ignition cables will transfer the highest amount of energy while virtually eliminating noise interference from sophisticated electronics.

marine

Marine applications for ignition wires and the demands on the ignition wires have changed radically over the last ten years. From GPS equipment that can find you to the nearest square foot; to fish finding equipment capable of discerning a good meal from an endangered species; to the clearest sound system; Magnecor wires simply keep the noise from spark ignition systems from penetrating those devices.

industrial

6 Wire Ignition Switch Diagram

Industrial applications like spark-ignited furnace systems and natural gas transfer stations all demand the best noise suppression wires available to prevent disaster. Magnecor has been supplying KV85 and CN10 noise suppressive wire to industry for over 35 years. One test requires the Magnecor wire transferring spark energy over 150 feet without radiating noise. Only Magnecor wire can meet this rigid requirement.

CUSTOM WIRE SETS

Magnecor is the ONLY manufacturer of ignition cable that offers wire sets customized for any application. Recognizing the need to meet the endless combination of engines and ignition system combinations, Magnecor is able to customize an ignition cable set for you. With over a combined 100 years of engine and ignition system experience on staff, Magnecor can get you the exact solution for your ignition cable needs.

Ignition Coil Wire Resistance Chart

P 248.471.9505 | F 248.471.9506 | info@magnecor.com